Hello friends,

I’m an underwater welder, and one of the most common questions people ask me is:

“What kind of things do you weld underwater?”

Well, underwater welding is not just about fixing ships. We work on many different kinds of structures — and some of them are huge and really important. In this blog, I’ll tell you about the main structures we work on, using simple words anyone can understand.

1. Ships and Boats

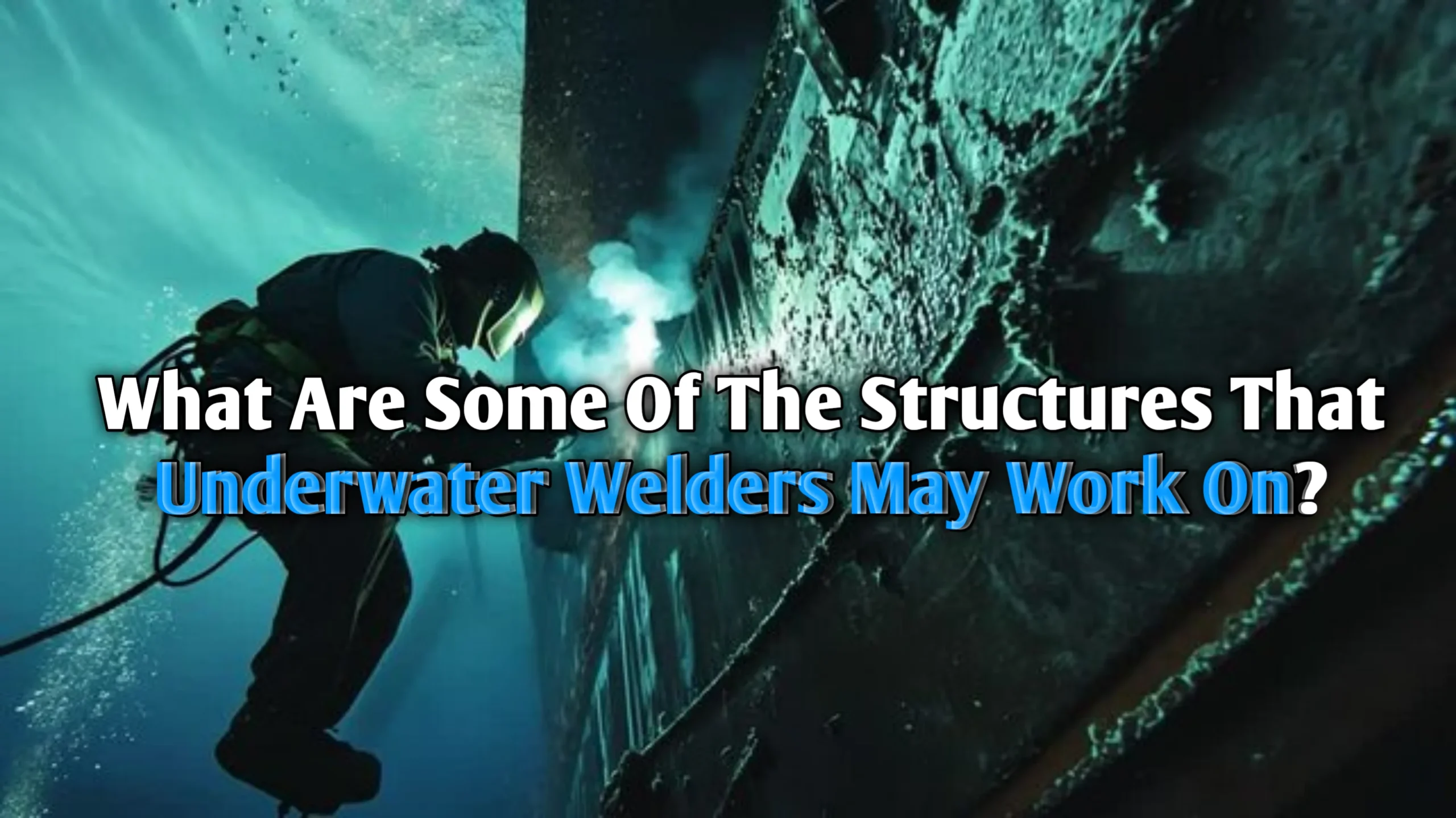

A big part of our job is repairing ships and boats. Sometimes a ship gets damaged under the waterline, or it needs parts replaced without bringing it out of the water. That’s where we come in.

We weld broken parts, patch holes, and fix metal frames. It’s common work, but it requires care — because we’re working with water pressure and heavy equipment.

2. Oil Rigs and Offshore Platforms

These are massive structures built out in the ocean to pump oil or gas. Underwater welders are needed to build and maintain the legs and support systems of these rigs.

It’s tough work — we may be hundreds of feet underwater, welding in deep, dark conditions. But the pay is good, and it’s a major part of the underwater welding industry.

3. Bridges and Piers

Bridges that cross rivers or oceans stand on big supports called pillars or piers. We often work on these pillars underwater — repairing cracks, fixing steel parts, or helping build new ones.

We also work on docks and piers where ships park. These structures are exposed to waves, water damage, and rust — so they need regular welding and inspection.

4. Dams and Waterways

Sometimes, we are called to work on dams, water tunnels, or locks. These are man-made structures that control water flow.

We may weld gates, steel walls, or even pipes inside the dam systems. It’s usually freshwater work, which can be a bit easier than working in the salty sea — but still needs full focus and safety.

5. Underwater Pipelines

Oil and gas need to travel through pipelines under the sea. These pipelines sometimes get damaged, shift, or rust. We are sent to weld the pipes, apply protective covers, or connect new sections.

This is dangerous and detailed work. We need to follow safety steps carefully because of high pressure and deep-sea conditions.

6. Subsea Equipment and Machinery

There’s a lot of equipment placed underwater — such as valves, pump systems, and anchor points. Welders are needed to install, fix, or remove these parts.

We may also assist engineers by cutting metal, welding brackets, or handling tools to secure machines in place.

How Much Do Underwater Welders Make In Georgia?

My Final Thoughts

Being an underwater welder means working on many different structures — from ships and bridges to oil rigs and underwater pipelines. Every project is different. Some are in shallow water near land, others are deep in the sea.

The job is not easy, but it’s exciting and full of variety. If you love working with your hands and aren’t afraid of the water, this might be the right career for you.

Thanks for reading — stay safe and keep learning!