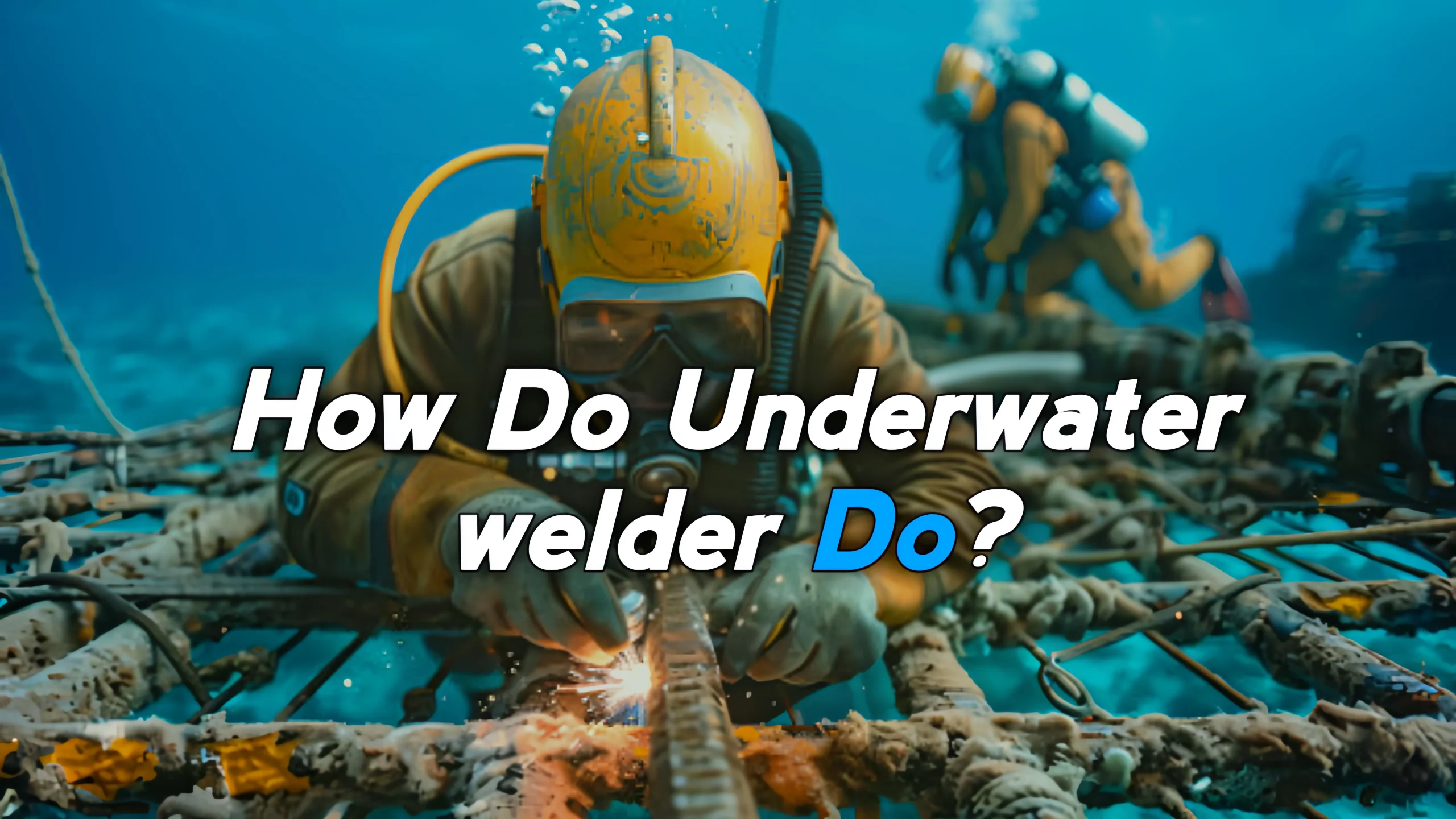

As an underwater welder, people often ask me, “What do you really do in underwater?” It’s a good question because the job isn’t like anything normal. Underwater welding is more than just fixing things—it’s working in places most people would never go. The water is cold, the currents are strong, and it’s hard to see. But what we do is important for keeping ships, pipelines, and oil rigs safe. It takes skill, strength, and a lot of courage. In the next part, I’ll share more about the specific work we do.

What We Do as Underwater Welders?

1. Welding and Repairs

One of the main parts of our job is welding metal structures underwater. Whether it’s fixing a damaged ship or repairing an underwater pipeline, we use different welding techniques like arc welding or TIG welding to join metal parts together. Sometimes, these repairs are due to corrosion, accidents, or natural wear and tear. The quality of our welding determines how strong and durable the repair will be, so precision is key.

2. Cutting Metal

In addition to welding, we often need to cut through metal, especially when parts are damaged beyond repair. Using specialized tools like underwater cutting torches or diamond wire saws, we remove the bad sections and prepare the materials for welding. Cutting metal underwater requires great focus, as clean cuts are needed to make sure the repairs go smoothly. Safety is a big concern here since we’re handling heavy tools in challenging environments.

3. Inspection

Before and after any work is done, we regularly inspect structures to look for signs of damage, wear, or corrosion. Using underwater cameras and sonar equipment, we check pipelines, platforms, and other structures to make sure everything is in good condition. Inspections help us find small issues before they become big problems, allowing us to fix them early and avoid costly repairs later.

4. Maintenance

Maintenance is a critical part of our job. To keep underwater structures in top shape, we perform tasks like cleaning, painting, and replacing old parts. Regular maintenance prevents bigger issues from happening and extends the life of the structures we work on. By checking up on everything regularly, we ensure that all systems run smoothly, helping to avoid more serious repairs down the line.

5. Installation of New Structures

Aside from repairs, underwater welders are also involved in building new structures. We help install things like underwater pipelines, subsea cables, and parts of offshore oil platforms. These installations are complex and require precision to make sure everything is securely in place. Once installed, we often test these structures to ensure they are functioning correctly.

6. Salvage Operations

Underwater welders are sometimes called in to assist with salvage operations. This means recovering sunken ships, equipment, or debris from the ocean floor. It’s a challenging job that requires both diving and welding skills. We may have to cut and remove parts of sunken objects or make them buoyant again to bring them back to the surface.

7. Constructing and Repairing Dams

We also work on projects involving dams and other water barriers. Whether it’s building new parts of a dam or repairing cracks and leaks, we need to make sure the structure is strong enough to hold back water. Working around dams requires careful planning and precision, as even small mistakes can lead to serious issues.

8. Supporting Marine Research

In some cases, underwater welders are hired to support marine research projects. This involves working on scientific equipment that is installed underwater, such as monitoring stations or data collection tools. Our job is to help set up and maintain this equipment so researchers can collect accurate data about the ocean and its ecosystems.

9. Supporting Marine Research

In some cases, underwater welders are hired to support marine research projects. This involves working on scientific equipment that is installed underwater, such as monitoring stations or data collection tools. Our job is to help set up and maintain this equipment so researchers can collect accurate data about the ocean and its ecosystems.

10. Demolition

Sometimes, instead of building or fixing something, we have to take things apart. Underwater welders are also trained to handle underwater demolition projects. We use explosives or specialized cutting tools to safely take down structures that are no longer needed, such as old oil rigs or pipelines. This work requires great care and planning to ensure the demolition is done safely and doesn’t harm the environment.

11. Dealing with Marine Growth

One of the unique challenges we face underwater is marine growth. Algae, barnacles, and other sea life often attach themselves to structures, which can affect their performance. We have to regularly remove these growths, especially from ships and pipelines, to keep everything running smoothly. Cleaning and removing marine growth is part of the maintenance work we do to ensure the long-term health of underwater structures.

12. Hyperbaric Welding

In some cases, we perform hyperbaric welding, which takes place in a dry environment created underwater. We use a pressurized chamber to seal off the work area and remove the water so we can weld in dry conditions. This type of welding is common when working at great depths and is essential for ensuring high-quality welds in extreme conditions.

13. Inspecting Offshore Wind Turbines

With the growth of renewable energy, many underwater welders are now involved in the inspection and maintenance of offshore wind turbines. These turbines are installed in the ocean, and it’s our job to check and repair the underwater structures that support them. This involves making sure the turbines are stable and free from corrosion or other damage.

14. Training and Certification

Underwater welding is not something you can jump into without proper training. We need to complete commercial diving school and get certified in both diving and welding. This training teaches us how to handle the dangers of deep-sea diving, operate welding tools underwater, and deal with emergencies. Regular re-certification ensures that we stay up-to-date with safety standards and technology advancements in the field.

15. Safety Protocols

Safety is the number one priority for underwater welders. We follow strict protocols to minimize risks while working in such challenging conditions. This includes wearing special diving gear, constantly monitoring our air supply, and using communication tools to stay in contact with our team. We are trained to avoid hazards like electric shocks, decompression sickness, and getting caught in tight spaces. Staying safe helps us do our job properly while protecting ourselves and others.

16. Emergency Response

Sometimes, things don’t go as planned. Equipment can fail, water conditions can change suddenly, or accidents can happen. As underwater welders, we are trained to handle emergencies quickly and calmly. Whether it’s dealing with a sudden issue underwater or helping a team member in trouble, we must stay sharp and ready for anything to ensure everyone’s safety.

17. Collaboration with Teams

We never work alone. Underwater welders often team up with other divers, engineers, and support staff. Good communication is key to making sure everything goes smoothly. Whether it’s a big repair job or a quick inspection, working together helps us complete tasks more efficiently and safely. By collaborating with our team, we can solve problems faster and handle complex jobs with ease.

These are some of the tasks we handle as underwater welders. I hope you found this helpful and that it inspires you to pursue a career in underwater welding.

How Do Underwater Welders Die?

Skills and Qualifications

To become an underwater welder, extensive training and certification in both commercial diving and welding are required. Not only do we need to master welding techniques, but we also must be skilled in diving and safety protocols. Many underwater welders undergo rigorous physical training, as the job requires strength, endurance, and the ability to work in confined spaces under pressure. Continuous re-certification ensures we stay up-to-date with evolving industry standards.

Personal Review As Underwater Welder

Being an underwater welder is a unique job that combines adventure and skill. Every time I dive, I face new challenges, like fixing broken structures and making sure underwater installations are safe. I take pride in my work because it helps keep important things running smoothly.

Working with my team is also great. We rely on each other to get the job done, and our teamwork makes everything easier. Although the job can be tough and requires us to follow safety rules, the feeling of overcoming these challenges makes it all worth it. For me, being an underwater welder is more than just a job; it’s a rewarding career that lets me do important work while exploring the ocean.